Sauce production

Ketchup、mayonnaise、salad dressing、custard、non-dairy creamer、coconut cream etc. are much important for our life which take better taste of foods.

Due to semi-solid status, sauce is not easy to handle during process, especially during sterilization.

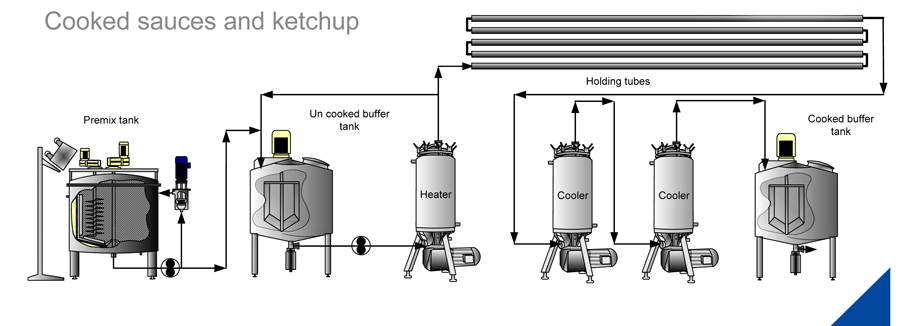

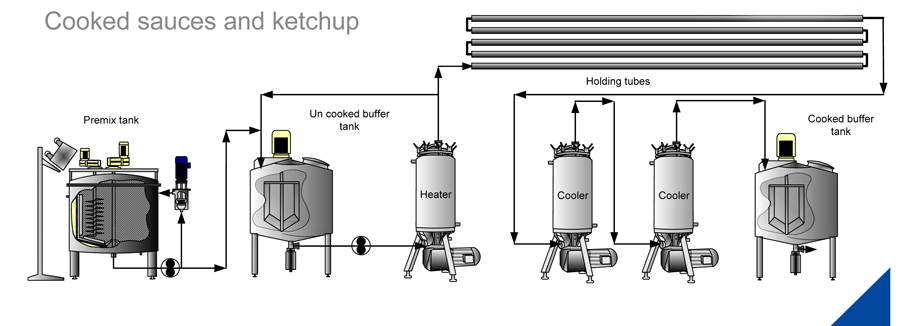

Cooked sauce normal process as below,

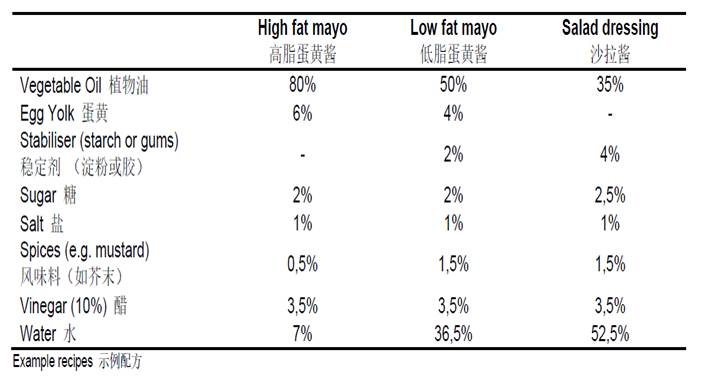

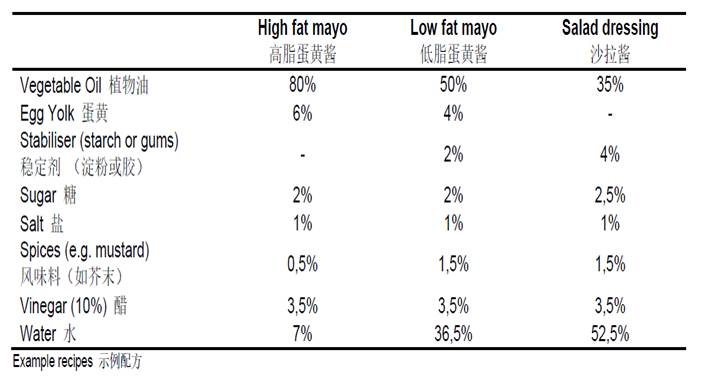

Mayonnaise&Salad dressing example formula:

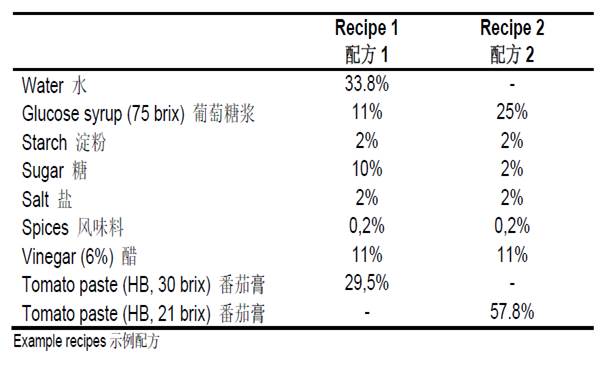

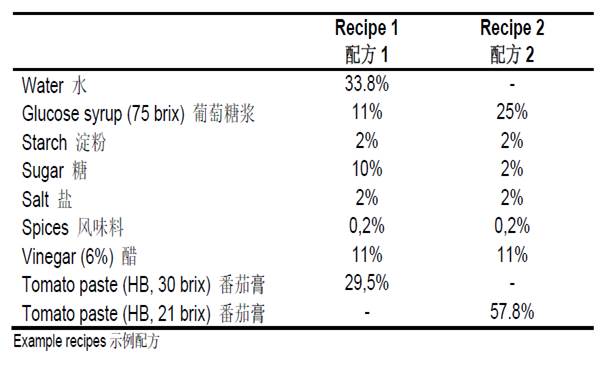

Ketchup example formula:

CCP Of Quality:

Formula

Mixing&emulsifying process

Oranoleptic index: color、viscosity、flavor

Physicochemical index: fat、protein、PH、salinity、acidity、denseness、density、brix

Microbiology index: process design、SOP、online quality control、microbiological detection

Storage&transporation: temperature、humidity、light etc.

Quality defect analysis:

Products seperate: emulsifying process not good, emulsifying structure not stable

Color change: too much oxygen involved in, fat oxidized

Taste: emulsifying not enough, incorrect thickener, low oil content

Unpleasant smell: overcooked,untreated metal ion

Microbiology out of limit: formula or processing defect, disabled microbiology control

Poor bake performance: formula defects, incorrect emulsifier and thickener

Solutions:

Our Vacuum mixer could used for pre-mixing tank which equipped bottom high shear mixer and agitator to get fully emulsified and homogenized sauce, dead corner free, no air bubble in final products.

All processing could be controlled automatically.

Scraper heat exchange used for sterilization and cooling after that, 100% sterilization guarantee to ensure products taste and shelf life.

+86 15921279869

+86 15921279869